Fischer went to school (Gymnasium) in Schaffhausen and then started an apprenticeship in his father's workshop as a coppersmith and making hand-driven fire-fighting pumps (Feuerspritzenmacher). In 1792, he set out as a wandering journeyman, his travels taking him to Germany, Scandinavia and England. On returning to Schaffhausen in 1794, Fischer took over his father's business. In 1802, he purchased a former mill in the Mühlental valley outside Schaffhausen, where he set up a small foundry for bells and the fire-fighting pumps, thus laying the foundation for today's international corporation. Around 1806 he was the first on the European continent to succeed in producing "crucible steel". Fischer was invited by the French Ministry of the Interior to settle in France but turned down the offer. He began creating cast steel alloys with other metals. In 1807, he created a low-alloy manganese steel, in 1814 so-called yellow steel with copper, in 1819 a silver-steel alloy and in 1823 steel with chromium.

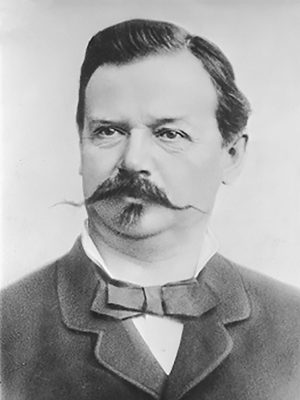

Johann Conrad Fischer

Company founder

(14 September 1773 - 26 December 1854)

More than 200 years ago, the company pioneer laid the foundation for today's Georg Fischer Corporation. In 1802, he set up a small foundry near Schaffhausen in Switzerland and very soon he began exporting abroad. In 1827 this tireless inventor succeeded in manufacturing malleable cast iron. Johann Conrad Fischer picked up ideas and gained inspiration from his many travels to countries such as England, France, Germany and Austria. In 1854 he passed the company he had founded on to his son Georg Fischer I, who had until then run the works in Austria.

Personal history

Expansion

The nickel steel alloy developed by Fischer in 1824 brought the company orders from Austria, France, Germany and England. The decisive step forward was the switch from nonferrous heavy metals such as bronze, cooper or brass to iron and steel. The rapidly expanding watch, textile and machine-making industries had an insatiable demand for these metals, which were cheaper and, at the time, "leading edge". Around 1825, Fischer began to produce solely steel and files, leaving off manufacture of his traditional products. The new products also opened up new markets for Fischer. Whereas the output from his copper foundry in the period 1811-1816 found customers mainly in the Canton of Schaffhausen, German-speaking Switzerland and southern Germany, his steel manufacture widened the scope to French-speaking Switzerland (the watch industry in the Jura), France, Germany and Austria.

A tireless inventor

In 1827 Fischer succeeded in manufacturing malleable cast iron. His last alloy – which he called Fischer metal – was cast steel containing one third copper. Fischer did not live long enough to see this invention used in railway axle boxes. Except for making files, Fischer did not consider the possibility of processing the steel himself. During Fischer's lifetime, what was later to become a large corporation was still a company managed along patriarchal lines. Fischer saw himself as an inventor rather than as an entrepreneur. In 1819, he helped set up a steel factory in La Roche near Montbéliard in the Franche-Comté and later concluded license agreements with companies in London and Liège. Since Austria was the only country with patent legislation, Fischer had almost all his inventions patented in Vienna. This explains why Austria was the first country in which Fischer expanded. He also set up steel foundries in Austria: at Hainfeld in 1827, Traisen in 1833, and Salzburg in 1839. He appointed his sons Georg, Berthold and Wilhelm to manage these works.

Inspiration from travel

In 1814, in the wake of his initial successes and the lifting of the Continental embargo, Fischer travelled to England and published his impressions in a Journal. On his journey through the English Midlands, he was a critical observer of the upheaval that later became known as the Industrial Revolution. His subsequent travels took him back to England as well as to France, Germany and Austria. Fischer's journals bear witness to the industrial and technological leaps that Europe was taking at the time. Fischer also used his skills and knowledge to benefit his native city. In 1797-1798 he was a member of the Kleiner Rat or Municipal Council. In 1801, he was appointed Mining Administrator for the exploitation of the Bohner iron ore mines, a post he held until 1851. From 1828 to 1846 he was a Grossrat or member of the Council Executive. In 1831, he was Federal Diet delegate for Schaffhausen, from 1831 to 1835 the city's first Mayor (Stadtpräsident) and a member of the Municipal Parliament until 1847. He had a wide circle of friends , both in Switzerland and numerous European countries, with whom he regularly corresponded. Among his correspondents were the sons of James Watt , the inventor of the steam engine, and the physicist Michael Faraday. Fischer was married to Katharine Fischer-von Waldkirch and was one of the outstanding personalities of Schaffhausen in the 19th century.

Please accept all cookies to view the external content.

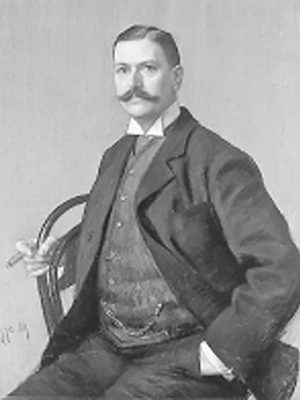

Georg Fischer I

(14 July 1804 - 3 October 1888)

The founder's son assumed responsibility at an early age. He was only 23 years old when he was appointed to manage the mill his father had founded in Hainfeld, Austria. In 1833, he bought a company in Traisen, also in Austria, where his brother Berthold later ran a foundry making malleable cast iron and steel. In 1854 Georg Fischer I inherited the Schaffhausen works on the death of his father and completely reorganized them. Ten years later he sold them to his son Georg Fischer II. Georg Fischer I ran the Hainfeld mill until his death in 1888.

Personal history

After his schooling in Schaffhausen and training at the Polytechnical Institute in Vienna, at the age of only 23, Georg Fischer I took over running the Hainfeld works founded in 1827. His father granted him a five percent stake in the firm, which was valued at 10,000 guilders. The son had to pay interest on the remaining 95 percent, which remained the father's property. In return, the son was entitled to one third of the profits. In 1833, Georg Fischer I bought a plant consisting of the cast steel works in the so-called "Auwerk", the file factory in the village and a spindle works in Traisen, Lower Austria, where his brother Berthold (1807-1879) later operated a foundry for malleable cast iron and steel. In 1835, the Hainfeld plant won the bronze medal at the Austrian Commercial Products Fair. The Fair Report stressed that orders for Fischer's products had increased to such an extent in a short time that he was already able, in 1833, to expand the Hainfeld works by the acquisition of a hammer mill in Traisen near Lilienfeld. What prompted Fischer to set up business in nearby Traisen was the availability of water power and the fact that he could obtain charcoal pig iron from a foundry in the vicinity. In Traisen, the cast steel was formed into spindles for spinning machines for use in the cotton industry.

An industrial network

Georg Fischer I also soon built up a network with the local industrialists. In 1833, he married his first wife, Seraphine Reiter, the daughter of the scythe manufacturer Leopold Reiter in Opponitz. One of the reasons that Johann Conrad Fischer opened his mill here was the region's flourishing scythe industry. In 1854, Fischer inherited the Schaffhausen works from his father and in 1855 he began to completely reorganize and modernize the mills, which had been closed. In the meantime, his son, Georg Fischer II, was running the family business in Hainfeld. By the end of the 1850s, the reorganization of the Schaffhausen works had been completed, and in 1864 Fischer sold them to his son, Georg Fischer II. By 1856, Hainfeld was already employing over 150 people, many of them from the parent company in Schaffhausen. When, in 1886, Georg Fischer – by then over 80 – announced that he was moving his Viennese sales office, which now included a department for the exchange of files, his crucible steel factory was producing a wide range of crucible steels that were rolled or hammered into rods and plates. His range included hammers, anvils, rollers, scissors, drills, chisels, thread cutters, bench vices, spanners and wrenches, "all manner of machine knives", files, rasps and saws, and he especially mentioned the "sharpening of dull files". The product range was largely similar to that offered by Schaffhausen, which in the meantime had begun offering several popular articles. Georg Fischer I ran the Hainfeld mill until his death in 1888.

Please accept all cookies to view the external content.

Georg Fischer II

(15 December 1834 - 12 August 1887)

Georg Fischer II, the founder's grandson, assumed management of the Schaffhausen works from his father Georg Fischer I in the autumn of 1856. In 1860, he added soft casting (malleable casting) to the production programme. He then had the name of the company changed to "Georg Fischer Schaffhausen, Weicheisengiesserei, Gussstahl- und Feilenfabrikation". In 1864 Georg Fischer II was the first in Europe to manufacture pipe fittings using the malleable casting technique. In the same year, he bought the company from his father. The +GF+ trademark has been in use since 1890. The company's first logo was a fish in the shape of the letters GF. Over the years, this mark developed into the current logo +GF+. The two crosses represent stylized fittings.

Personal history

From the age of 7 to 16, Georg Fischer II lived in Schaffhausen with his grandfather, the company's founder, Johann Conrad Fischer. He went to school there, and it was his grandfather who initiated him into the art of manufacturing cast steel and steel casting and taught him how to forge the product into files. He probably attended the Polytechnical Institute in Vienna. Following his grandfather's death, he spent a short time in his father's mill in Hainfeld. In late autumn 1856, he was entrusted with running the works in Schaffhausen, which had been inoperative since the death of J.C. Fischer.

Introduction of malleable casting

In 1860, Georg Fischer II revolutionized the company's manufacturing programme. Using a technique developed by his grandfather, he began the commercial production of malleable soft cast steel ("Weichguss"). The Mühlental works had started out as a pure high-grade steel mill, where crucible steel was forged into knife blades, files, shears, punches and dies, rifle barrels, etc. With the introduction of malleable casting, though, the emphasis was now on casting. Accordingly, the name of the company was changed in 1861 to "Georg Fischer Schaffhausen, Weicheisengiesserei, Gussstahl- und Feilenfabrikation". After having managed the firm for some time, Georg Fischer II bought the company from his father Georg Fischer I in 1864. It was he who developed the Schaffhausen foundry established by his grandfather from a handicraft business into a large manufacturing plant. Starting in 1864, he was the first in Europe to use malleable casting to manufacture pipe fittings. They were superior to the traditional wrought-iron fittings in terms of both quality and price and were an immediate success. The expansion of infrastructure (gas and water utilities, sewage installations) then taking place in European cities quickly expanded the market for these fittings. They were also highly suitable for serial manufacture and thus for industrial-scale production. The range of models expanded rapidly: The first +GF+ price list offered 91 different models. By 1890 this had grown to 750 and by 1925 to 8615. The production of fittings went hand in hand with the use of a trademark by the company. The original mark, a fish shaped out of the two letters GF, developed over the years into the current logo +GF+. The two crosses represent stylized fittings.

Growth and stock market crash

In 1877, Georg Fischer II began with the production of steel casting, thus opening up a further area of manufacturing. In 1881, he announced to his clientele "that the expansion and improvement of my equipment has enabled me to supply cast steel pieces that have some weight but are simple in form and inexpensive in price." Georg Fischer II thus exploited a process that his grandfather had developed but not used commercially. However, the economic situation in the Schaffhausen region was sluggish, and no real upturn took place until the Franco-Prussian war of 1870-71, after which there was a boom during the Wilhelminian "Gründerjahre". This trend is also reflected in the number of people employed at the reorganized Fischer works. The obituary on Fischer related that employment had stagnated at 30 to 42 workers between 1863 and 1868 and then climbed from 67 to 210 in the years 1871-1873: "House after house was built, mill after mill, along with warehouses, canteens and workers' housing, so that the establishment has now become a small village." What had become a familiar picture in other industrialized regions of Europe now began to take shape in the Mühlental valley. However, the severe Long Depression cast a damp over the second half of Georg Fischer II's career. Following the steady growth, the crash was staggering. In 1877, the mill employed only 104 workers and clerical staff, only half as many as four years previously. Georg Fischer II died in 1887 without the company ever achieving the employment peak it had reached in 1873, the year the Vienna stock market crash precipitated the crisis.

In addition to his work in the family firm, Georg Fischer II helped set up the Schaffhausen Handelsbank and a twine factory in Flurlingen near Schaffhausen as well as the Luisenthal spinning works in Thuringia.

Please accept all cookies to view the external content.

Georg Fischer III

(12 September 1864 - 19 January 1925)

Following the death of his father, Georg Fischer III assumed management of the firm in 1887 at the tender age of 23 years. This period saw the company enter a new era in which Georg Fischer became a large corporation that grew beyond national boundaries. The greatest achievement of Georg Fischer III was setting up a steel foundry for large cast steel pieces. As a result of this move, steel casting became a major area of production for the company.

Personal history

After attending school in Schaffhausen, Georg Fischer III first registered at the University of Geneva. He then did practical training in Wasseralfingen (Germany), where he learned the art of malleable casting. After his practical training, Georg Fischer went to Dresden to study engineering at the Royal Saxon Polytechnic (Mechanical Engineering department). Here he attended lectures on mechanical engineering, metallurgy and chemistry. However, he had to discontinue his studies after three semesters because his father died and he was called on to take over management of the company.

Expansion of fitting production

Georg Fischer III devoted himself to expanding the business his father had bequeathed to him and to realizing his father's development plans. As early as 1888, he decided to discontinue the production of files in order to use the premises for the expansion of fitting manufacture. One forge gave way to a new fitting foundry, while another – a file mill that had been mothballed – was transformed into a thread cutting workshop. In order to put steel casting on a new footing, Georg Fischer III installed a Siemens-Martin coke oven in the new foundry he had built in 1890. He thus not only significantly expanded the plant but also improved quality in a bid to meet the rapidly growing demand for cast steel from the electricity industry and the railways. By 1889, Georg Fischer III was delivering cast-steel locomotive wheels and by 1890 magnet wheels from Martin cast steel to Maschinenfabrik Oerlikon in Switzerland and to AEG in Berlin. The payroll had counted 183 employees in 1887; within nine years it more than tripled owing to the expansion, and as the century drew to a close Georg Fischer had 552 employees. It was definitely no longer a medium-sized company! By the turn of the century, the number of employees had further increased to over 1,600.

A booming industry

Georg Fischer III had more luck with the economy than his father. In the mid-1880s, a prolonged upswing began that lasted, with brief interruptions, until the outbreak of the First World War. This boom was driven mainly by the new electrical engineering and chemical industries, which compounded the growth produced by infrastructure expansion and the appearance of the internal combustion engine. In 1895, Georg Fischer III opened a fitting mill in nearby Singen, a project that had already been envisaged by his father. The main reason this move was the effect of German tariffs, which were inducing many Swiss companies to set up operations in South Baden across the border. Another factor was the appearance on the market in the 1890s of malleable cast iron fittings from German competitors.

To keep the company growing, capital was needed, and Georg Fischer III met this need by transforming his firm into a joint stock company in 1896. At the same time, he pushed ahead with various social security benefits such as allowances for older employees, company canteens and extensive construction of housing for company employees. In 1898, he instituted the first workers' commission. A crisis of overcapacity and overproduction put a dent in the general economic upswing in 1901. The crisis did not leave Georg Fischer unscathed, and turnover plummeted. Open discord broke out in the Board of Directors, and in 1902 the banks forced Georg Fischer III to step down from the company management. However, he didn't simply retire but rather remained active in the industry. In 1907, he introduced in Switzerland the Heroult electric furnace for making cast steel and founded the Electric Steel Works in Schaffhausen, which he sold to Georg Fischer in 1917.

Please accept all cookies to view the external content.

Ernst Homberger

(5 July 1869 - 13 January 1955)

Ernst Homberger began his career at Georg Fischer in 1902 as the company's Commercial Director. Five years later he was appointed Managing Director. Under his leadership, GF grew and flourished. He opened new markets and built up sales organizations. His stewardship saw the acquisition of the Rauschenbach engineering works in Schaffhausen, Switzerland, and the Wagner & Englert GmbH fitting works in Mettmann, Germany. In 1929, he was appointed Chairman of the Board of Directors and became the Board's Honorary Chairman in 1954. With his strong personality and his dynamic business policies, Ernst Homberger shaped the company for more than half a century.

Personal history

Ernst Homberger attended school in St. Gallen and Zurich and commercial school in Neuchâtel before gaining practical experience at trading firms and banks in Zurich and London. He then worked for a bank in the West Indies. On returning to Switzerland in 1896, he joined the Rheinfelden power transmission works, still in the development phase. Within a very short time, he had advanced to the position of authorized signatory (Prokurist) and head of book-keeping.

Appointment as Managing Director

In 1902, Ernst Homberger joined Georg Fischer as Commercial Director, and in 1907 he was appointed to the newly created position of Managing Director. The banks had brought him in to manage the firm, and he soon became a part owner of Georg Fischer too. On his marriage in 1903 to the daughter of Johannes Rauschenbach – the Schaffhausen machine and watch manufacturer – he became the main shareholder of Maschinenfabrik Rauschenbach, which was acquired by Georg Fischer in 1921. In 1923, the General Meeting of Shareholders elected Ernst Homberger as a member of the Board of Directors, and he was immediately appointed its Delegate. From 1929 to 1954 he presided over the Board of Directors as its Chairman and in 1954 he was named Honorary Chairman of the Board of Directors.

Ernst Homberger was one of Switzerland's leading industrialists and he sat on the Boards of companies in industry (including Schweizerische Lokomotiv- und Maschinen-fabrik, Bindfadenfabrik Flurlingen, Salmenbräu Rheinfelden), banking (Swiss Bank Corporation) and insurance (Bâloise). In addition, he held a number of other posts: he was a member of the Council of the Swiss National Bank from 1932 to 1947 and was active in various associations of the mechanical engineering and fitting industries in Switzerland and abroad. He also headed the Schaffhausen watch company IWC starting in 1929, leading it through troubled times. In recognition of his achievements, Ernst Homberger was named doctor honoris causa of what is now the University of St. Gallen and an honorary citizen of Schaffhausen.

Entrepreneurial vision

Among the achievements of Ernst Homberger is the extension of the social institutions at Georg Fischer. He created numerous residential colonies or quarters in Schaffhausen and Singen. In 1919, he founded the Employees' Pension Fund and in 1927 the Homberger Foundation, the aim of which was to promote vocational training for children of Georg Fischer employees. In addition to his achievements in the social field, Ernst Homberger continued to steadily expand the business of Georg Fischer. With the acquisition of the Maschinenfabrik Rauschenbach in 1921, Georg Fischer entered the engineering and grey cast iron sectors. In the 1920s, Rauschenbach expanded its production of truck wheels and began the manufacture of foundry and machine-tool machinery. In 1933 Ernst Homberger also founded the Britannia Iron and Steel Works Ltd. in Bedford, thus impelling the company's expansion in England. These acquisitions marked the beginning of Georg Fischer as a Corporation. The actual conversion into a global company, though, began after the Second World War, when Ernst Homberger was already retired.

Please accept all cookies to view the external content.